PRODUCT LIST

Hansen MVP Valve Stations

The MVP valve is well suited for applications including pumped liquid feed to evaporators, liquid make-up to flooded and recirculator vessels, liquid injection for screw compressors, hot gas defrost to evaporators, and evaporator pressure control.

Up to six separate functions are possible: stop valve, strainer, control valve (solenoid/pressure regulator/ motorized), check, hand expansion, and stop valve.

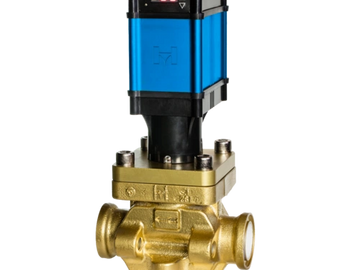

Hansen Solenoid Valves

Solenoid Valves come in 5/32" to 6" (4 mm to 150 mm) sizes. Options include close-coupled strainers and pilot lights. Solenoid coil connection styles can be standard 1/2" fitting for conduit, DIN plug coils, or coil with junction box.

Applications: Some typical applications include high pressure or low pressure liquid feed, recirculating liquid control, defrost hot gas control, suction shutoff, purge line, and wherever a strong-opening, tight-closing valve is required.

These advanced design, strong bodied, precision manufactured solenoid valves control the on-off flow of refrigerant. They are superior in their ability to overcome dirt and sticky oil during opening and closing, and operate smoothly even in an oil-free “dry” system.

Hansen Technologies introduces the HS4D Two Step Solenoid Valve. The HS4D is based on the same strength, reliability, design principles and Hansen Technologies introduces the HS4D Two Step Solenoid Valve.

The HS4D is based on the same strength, reliability, design principles and craftsmanship as the standard Hansen HS4A Solenoid Valve—with added versatility.

This flanged, industrial refrigeration duty solenoid valve is very simple and compact but rugged in construction. Body is plated steel alloy with a direct lifting stainless steel plunger that contains a teflon seat that closes on a stainless steel orifice. When electrically energized, seat opens wide; when de-energized, it closes to stop flow in the arrow direction on the valve body.

This flanged, heavy duty, pilot-operated, industrial refrigeration solenoid valve controls the flow of refrigerant. When electrically energized, a slight pressure difference across the valve causes it to open wide; when de-energized, a spring promptly closes the main Teflon seat to stop all flow in the arrow direction on the valve body.

This heavy-duty HS8A refrigeration solenoid valve is flanged, compact, and pilot-operated. It is now more dirt resistant, erosion resistant, and corrosion resistant than other similar refrigerant valves. A dirt controlling Teflon piston seal helps prevent sticking. The valve body has improved, erosion resistant flow passages.

All Hansen solenoid valves utilize a one-size encapsulated, watertight coil. These coils are strong and efficient, requiring only 16 watts of power. All common voltages and frequencies are available.

Hansen Strainers

These rugged Strainers (Filters) are specifically designed to facilitate the removal of foreign materials from refrigeration systems. Strainers help prevent damage to valves and other components, thereby reducing costly service and downtime. They can also be installed as a separate unit. They are available in 1/2" to 6" (13 mm to 150 mm) sizes.

Hansen Pressure Regulators

The HA4AM can be ordered “less motor,” which includes control module, cam, and motor-mounting bracket. A three port bonnet with blanking plugs is standard on the HA4AM (up to 4²/100 mm port) so that other pilots can be field installed if required.

The “M” feature can also be ordered with other valve combinations, most commonly the HA4ADM Dual Pressure Regulator with motorized pilot. All material Features for the HA4A modular pressure regulator apply to the HA4AM.

Features 3/4" thru 6" flanged and weld-in, a manual opening stem, and various models for control of temperature, inlet, outlet or differential pressure.

These regulators are commonly-used in small capacity applications or as a pilot valve to operate larger main valve and a non-atmospheric relief to low side (HA2BK). These regulators are furnished with flanges for FPT (Female Pipe Thread, American National Standard, tapered), socket weld or weld neck (to match American Pipe Schedule 40), or ODS (Outside Diameter Sweat) for copper tubing size connections. They have an inlet pressure gauge port.

Hansen Gas Powered Valves

These heavy-duty, flanged, gas-powered suction stop valves are designed to control the flow of refrigerant in large industrial and commercial applications.

They remain normally open via a spring and require no pressure drop to operate. Valves are normally installed on their side for better conveyance of liquid overfeed or oil and to avoid trapping.

A single pilot solenoid valve is required to control a higher pressure refrigerant gas which closes these valves during defrosting.

These heavy-duty, durable, ductile iron or cast steel body, gas-powered suction stop valves are designed to control the flow of refrigerant in large industrial and commercial applications.

They remain normally open via a spring and require no pressure drop to operate. A single pilot solenoid valve is required to control a higher pressure refrigerant gas which closes these valves during evaporator defrosting.

If an electrical power failure occurs during the hot gas step of a defrost cycle, the auxiliary pressure pilot valve will keep main valve seat closed until pressure inside evaporator is reduced to the pressure setting on the pilot.

The HCK5D valve has an internal, controlled bleed-down (equalize) feature which will not allow the main seat to open until the pressure across the valve is at a lower, safer pressure differential. This eliminates the need for a separate bleed-down solenoid valve, greatly simplifying piping and reducing installed costs.

If a loss of power occurs during defrost, evaporator pressure is utilized to keep the main valve seat closed until bleed-down is complete.

These strong, heavy-duty, gas-powered solenoid valves are designed to control the flow of refrigerant in large commercial and industrial applications.

They require no pressure drop to operate and have no internal bleed to suction.

A dual pilot solenoid valve assembly introduces a high pressure refrigerant source which closes these valves. To open valves, pressure is bled-off back through the low pressure bleed pilot valve and upstream line pressure plus the spring causes the valve to open wide.

Hansen Check Valves

These flanged, heavy-duty, piston-type check valves control the flow of refrigerant.

Valves open wide for flow in the direction of the arrow on the valve body. Valves close tight when flow reversals occur.

Valves open when inlet pressure exceeds outlet pressure (1 psid [.07 bar] minimum), thereby lifting the piston/seat assembly and allowing flow through the valve.

The HCK4 series of dependable, compact, rugged in-line check valves (disc type non-return valves) is ideally suited for refrigerant flow control applications.

Valves open wide for flow in the arrow direction on the valve body. Valves close quickly and reliably when flow reversals occur.

Plated bodies and stainless steel seat discs and springs enable them to withstand expected industrial refrigeration conditions.

Check valves can be mounted in any position and close coupled to other valves.

The HCK4 “LR” series of in-line gravity drain check valves are dependable, compact, and rugged.

The HCK4 “LR” gravity drain check valves feature a low, wide-opening pressure differential suitable for liquid transfer systems and other low-pressure-drop applications.

In addition, an optional, specially-designed adapter allows direct replacement of existing 3" and 4" Wolf-Linde and HA Phillips gravity drain check valves without repiping.

HSCK Stop/ Check Valves (durable, carbon-steel-bodied valves) are a combination stop valve and normally-spring-closed check valve.

Valves open wide for full flow in the arrow direction on the valve body and promptly reseat when reverse flow occurs.

Stainless steel valve stems facilitate positive manual closing while Teflon disc seats assure reliable, long-life seating.

Use of these combination valves reduces pressure drop, minimizes space requirements, and simplifies installation.

Hansen Shut-Off Valves

The advanced design and materials of Hansen threaded refrigerant shut-off valves make them far superior to commonly-available products, especially in regard to non-leakage of seats, stems, and bonnets. Anyone who has experienced the failure of a shut-off valve at a crucial time will take care to insist upon these highly-reliable valves.

Socket weld steel bodies permit these valves to be quickly and easily welded directly into piping without the inconvenience of pipe threading or using bulkier iron-flanged valves with socket weld steel flanges requiring bolts, nuts, and gaskets.

Compared to butt weld valves, the Hansen socket weld bodies allow quicker welding, easier pipe alignment, and cleaner pipe and valve interiors.

Hansen low pressure drop refrigerant shut-off valves are designed to be butt-welded directly to steel piping, thereby eliminating potential leaky flanges or threaded joints and simplifying installation.

The “heart” of Hansen shut-off valves is the patented no-leak seal-plus-stempacking design. This seal design is used exclusively on Hansen shut-off valves and virtually eliminates stem seal leakage.

Hansen Hand Expansion Valves

These precision-calibrated, adjustable, slotted plug flow regulating valves (hand expansion valves) are ideal for metering or flashing expansion of liquid refrigerants.

All valves have near linear flow characteristics per turn open and are tight closing with Teflon seats. These valves have stainless steel stems with back seating for seal replacement.

Bar handle or yellow seal caps distinguish them from shut-off valves.

Suitable for ammonia or halocarbons.

Hansen Pressure Relief Valves

Hansen EZ-SRV Cartridge Pressure Relief valves protect refrigeration pressure vessels and other refrigeration system components from excessive pressure. If an abnormally high pressure occurs, the cartridge pressure-relief valve will open to relieve the excess pressure, preventing potential damage to equipment and injury to personnel.

Designed to provide emergency relief from excessive pressure in refrigerant-containing vessels, they are built in strict conformance with ASME Boiler and Pressure Vessel Code requirements for safety relief devices.

Each valve bears the ASME code symbol of certification (UV). Their capacities are rated by the National Board of Boiler and Pressure Vessel Inspectors. These tamper-resistant valves are accurately set and sealed by qualified technicians at the factory

Hansen rupture disc assemblies (RDAs) are used to indicate which pressure-relief valve has discharged. A pressure-relief valve will re-seat after discharging. However, a rupture disc remains open after bursting. (A rupture disc is not a stand alone safety device.) An installed pressure gauge or switch (required by code) provides a visual or electronic indication that the rupture disc has burst.

Hansen Gauge, Purge, and Transducer Valves

Hansen's specially designed Gauge, Purge, and Transducer Valves feature tough, forged steel bodies, compact size, and polished stainless steel stems.

Their patented o-ring plus packing dual-seal design and polished stainless steel stems provides leak-free packing. The safety stem design prevents removal of stem from body or stem "blowout".

Hansen Oil Temperature Valves

A 3-way mixing valve that operates with the use of an internal thermostatic element. As oil is circulated through the screw compressor, it picks up heat from the compressor. The hot oil is circulated past the thermostatic element inside the valve and it is also fed to a heat exchanger, which provides cold oil to the opposite side of the valve.

Hansen Float Switches

The Hansen Refrigerant Float Switch (HLL series) is used to electrically indicate or control a liquid level by opening or closing a single pole, double throw (SPDT) switch. Its simple, reliable design provides long life performance for almost any application.

The HT100, HT200, and HT300 High Side Floats (Float Drain Regulators) are typically used to drain condensers to chillers, recirculators, controlled pressure receivers, or flooded evaporators; to drain hot gas supply mains; or to drain liquid condensate from heat reclaim coils.

The HD101 Defrost Drainer, a variation of the HT100 high side float, has an adjustable vent valve bypass to fine-tune individual systems which may experience evaporator defrost gas binding.

Hansen Auto Purgers

AP Auto Purger

The AP has at least two to three times the air removal capacity of any competitive purger, and up to ten times other smaller purgers. With models available to purge up to 8, 16, and 24 points, the AP features automatic startup with electronic control. Purge points can be individually adjusted to meet system requirements. Includes an automatic water bubbler; Optional NEMA 4 rated enclosure also available.

NEAP Mini Auto-Purger

The Non-electric NEAP AUTO-PURGER is ideal for smaller systems up to 100 tons (350 kW) ammonia. The simple design of the NEAP AUTO-PURGER features fully automatic startup, like the other AUTO-PURGERs, and is generally used to purge a single point.

For use with ammonia refrigeration systems.

Auto Purger Plus

The AUTO-PURGER PLUS (APP) is a totally automatic, electronically controlled non-condensible gas (air) and water purger for reducing the energy costs of operating an ammonia refrigeration system.

The APP is shipped preassembled, prewired, insulated, and includes an automatic water bubbler, a relief valve, and an isolation service valve package.

APM / APMF Auto Purger

A compact version of the original AP Auto-Purger, the APM Auto-Purger is ideal for medium size systems, up to 200 tons (703kW). Like the AP, the APM features automatic start-up with electronic control.

Designed for up to four purge points, an electronic "brain" searches for non-condensible gases in the system and purges at those points where air is present.

The APM includes an automatic water bubbler and comes standard with a NEMA 12, 13 control cabinet.

Hansen Motorized Control Valves

Motorized Control Valve

Hansen’s new ½” thru 4” Motorized Control Valve is a direct motor actuated valve designed for operation in Dx, liquid makeup, temperature, pressure and level control applications for a wide variety of refrigerants.

With its industry leading Safe Working Pressure (SWP) and MOPD rating of 800 PSIG, this valve also features water tight, weather proof, IP 67 rating for reliable outdoor use along with factory set plug-and-play logic for quick and hassle-free installation.

Hansen Level Controls

Single Point Sensor and Switches

These compact Single Point Level Sensors and Switches are economical solutions for reliable and accurate level detection. They are designed to detect the presence of ammonia or halocarbon refrigerant liquid (but not oil) at a specific location in vessels containing refrigerant by capacitance-type, non-optic sensing.

SEE LEVEL Refrigerant Liquid Indicator

Hansen SEE-LEVEL™ Refrigerant Liquid Indicators provide simple indication of true liquid levels in industrial and commercial refrigeration systems.

Vari Level Adjustable Level Control

The Hansen Vari-Level Adjustable Level Control provides excellent level control and monitoring flexibility for industrial and large commercial refrigeration systems. It takes the place of multiple single point level switches on new or existing refrigerant vessels.

Techni-Level Level Transducer Probe

These specially-designed Techni-Level Transducer Probes with 4-20 mA output are for refrigerant level control in computer operated industrial and commercial plants.

Receiver Level Transducer Probe

Designed to be inserted directly into refrigerant receivers and facilitate the continuous measurement of refrigerant liquid levels.

Gauges

Winters Pressure Gauge

Pressure gauges and vacuum gauges allow users to monitor the pressure of air and noncorrosive fluids in pumps, filters, compressors, and regulators. Boiler gauges measure both the temperature and water pressure in boilers.

Hisco Pressure Gauge

Differential pressure gauges (analog and digital) measure and control pressure drops across filters, strainers, separators, valves, and pumps.

Thermometers

Weiss Vapor Actuated Dial Thermometer

Offered in 3-1/2" and 4-1/2" dial sizes, these thermometers are furnished in four stainless steel case configurations for direct, surface or panel mounting. The following coding chart illustrates a wide variety of bulb styles, capillaries and process connection fittings.

The versatility of configurations makes these thermometers well suited to a wide range of applications including hot and chilled water pipeline systems, tanks and air ducts.

Latex Tubings

Latex Tubing

All products are extensively leached, washed and surface treated to minimize protein levels – 99% protein-free.

The technical information supplied consists of typical product data and should not be used for specification purposes.

Pressure Controls

Dual Pressure Control

The P70, P72, and P170 Controls for Dual Pressure Applications are designed primarily for use as combination high and low pressure controls on commercial refrigeration and air conditioning applications.

These controls are available in several pressure ranges and are compatible with most common refrigerants. Ammonia compatible models are also available.

Open High Pressure Control

P70C, P70D P170C and P170D models with Single-Pole Single-Throw (SPST) Open-high switch action are the most popular models, and are typically used for high-pressure cutout. The C models are automatic reset. Some P70C, P70D P170C and P170D models are UL Listed as refrigeration pressure limiting controls.

High Pressure Cutout Control

P70C, P70D P170C and P170D models with Single-Pole Single-Throw (SPST) Open-high switch action are the most popular models, and are typically used for high-pressure cutout. The D models have a manual reset lockout mechanism. Some P70C, P70D P170C and P170D models are UL Listed as refrigeration pressure limiting controls

Oil Failure Cutout Control

The P28 and P128 Series Lube Oil Controls provide dependable and economical oil pressure cut-out for pressure-lubricated refrigeration compressors. The field-adjustable pressure differential of these controls provides compressor operation according to the manufacturer’s specifications.

The P28 and P128 controls operate by measuring the net lube oil pressure and de-energizing the compressor if the pressure falls below the differential setpoint.

Differential Pressure Control

These controls are available in several pressure ranges and are compatible with most common refrigerants. They may also be used on other non-corrosive fluid applications. Ammonia-compatible models are also available. Controls also are available in several different electrical ratings and switch configurations.

Replacement (Genuine and OEM Quality) Spare Parts